- Home

- |

- Products

- |

- PuraBead® Resins

- |

- IEX

- |

- Q PuraBead® Edge

Q PuraBead® Edge

Product overview

Q PuraBead® Edge is a next-generation strong AEX adsorbent, featuring a quaternary ammonium (Q) group attached to our advanced 65 µm PuraBead® Edge base bead. Our PuraBead® Edge resin is engineered for high resolution intermediate purification and polishing applications. This resin is ideal for achieving superior purity in bioprocess workflows without compromising throughput.

What are the key features of Q PuraBead® Edge?

- Improved resolution using our 65 µm PuraBead® Edge base bead

- Optimal balance of flow rate, binding capacity, and resolution to maximize productivity

- Demonstrated performance in polishing, plasmid DNA open circular (OC)/supercoiled (SC) separation, AAV8 purification and other applications requiring high resolution techniques

- Efficient processing of large volumes

In application: Resolution optimization in protein purification

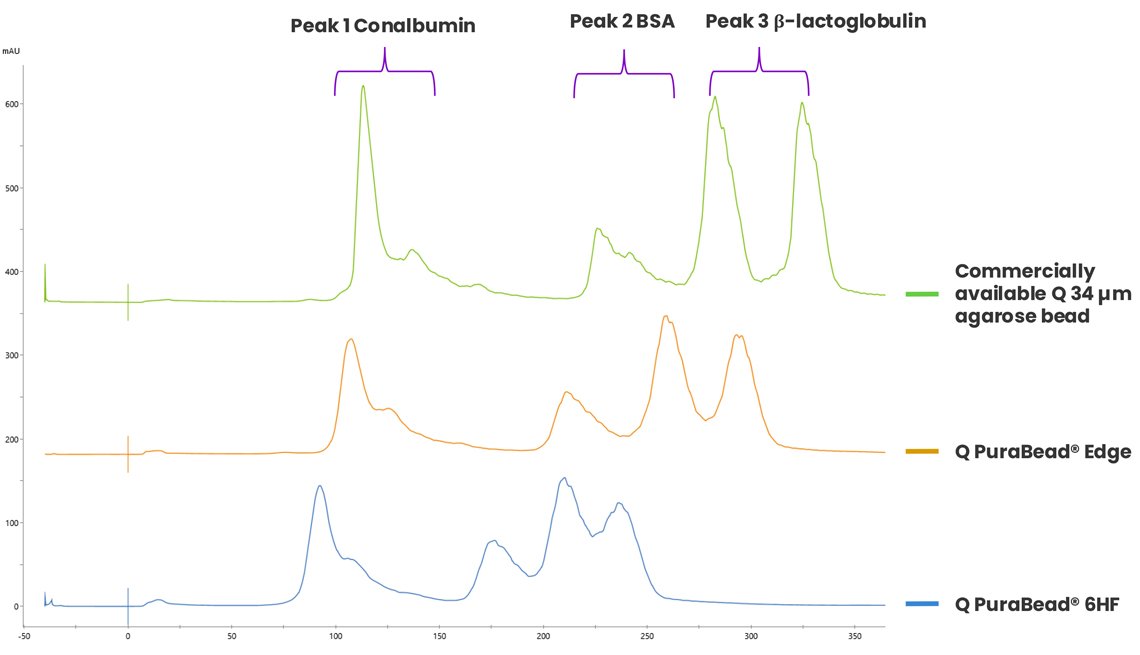

Q PuraBead® Edge is specifically engineered to deliver exceptional resolution in intermediate purification and polishing steps. In comparative studies using a protein mixture of Conalbumin, BSA, and β-lactoglobulin, columns packed with 65 µm Q PuraBead® Edge demonstrated a resolution improvement of over 200% between closely eluting peaks versus traditional 90 µm Q PuraBead® HF resins (see Figure 1). This enhanced separation capability allows researchers to achieve higher purity in fewer steps without compromising throughput.

Unlike resins with larger beads, which often produce broader peaks due to diffusional limitations, Q PuraBead® Edge maintains sharp, distinct separations even at elevated flow rates. It remains close to the resolution of much smaller, such as competitor 34 µm beads, but with significantly better flow properties and lower backpressure—providing an ideal balance of performance and process efficiency for modern bioprocessing demands.

This high-resolution performance does not come at the cost of process efficiency. Q PuraBead® Edge also excels in dynamic binding capacity, even under fast flow conditions. In residence time studies ranging from 1 to 10 minutes (with linear flow rates up to 300 cm/h), the resin demonstrated consistent binding capacity across all flow rates (see Figure 2).

The ability to maintain high performance at reduced residence times makes Q PuraBead® Edge an ideal choice for high-throughput environments, where speed, yield, and purity must work in concert. It delivers a compelling combination of resolution, capacity, and operational flexibility that supports both small-scale screening and large-scale manufacturing.

Figure 1: Resolution comparison between 90 µm, 65 µm, and 34 µm chromatographic beads.

_2025155-180807.jpg)

Figure 2: Graph showing the relationship between binding capacity and residence time when loading to 10% breakthrough with BSA.

In application: Plasmid DNA (pDNA) supercoiled (SC) and open circular (OC) separation

To meet the growing demand for high-quality plasmid DNA in gene therapy, Astrea Bioseparations offers a robust two-step purification process which combines a high-speed capture step using pDNAHERO®, followed by a high-resolution polishing step with Q PuraBead® Edge. The goal is to efficiently isolate supercoiled plasmid DNA while removing host contaminants and separating out open circular and degraded forms. Many manufacturers face challenges with slow processes, limited resin capacity, and poor resolution between isoforms—all of which can impact product quality and scalability. This two-step purification process is designed to meet a critical need in gene therapy manufacturing; producing high-purity, supercoiled plasmid DNA at scale.

As demand increases, many teams face bottlenecks due to low-capacity resins, long run times, and poor separation of isoforms. The combination of pDNAHERO® for high-speed capture and Q PuraBead® Edge for high-resolution polishing addresses these challenges directly. The first step rapidly removes bulk impurities and concentrates the plasmid. The second step—using Q PuraBead® Edge—separates supercoiled from open circular and other forms, improving product quality and consistency. In one example using an 8 kb plasmid, 88% recovery was achieved with clear separation of isoforms at a 2-minute residence time, showing strong performance in both speed and resolution. The 8 kb plasmid was processed through a 2.5 mL Q PuraBead® Edge column (10 mm ID × 3.2 cm bed height) following capture on pDNAHERO®10. From the pDNA load, 88% of plasmid DNA was recovered, while the chromatogram in Figure 3 shows separation of isoforms with distinct elution peaks (UV 260 nm) and stable conductivity control. AGE gel confirms effective removal of open circular (OC) forms and enrichment of supercoiled (SC) plasmid in elution fractions E1 and E2 respectively in Figure 3. Loosely bound RNA impurities were cleared in the post-load wash, as indicated by the UV signal without detectable pDNA bands, reduces processing time.

The 65 µm monodispersed particle size of Q PuraBead® Edge enhances separation performance by reducing zone broadening and improving peak resolution. Its strong anion exchange (AEX) functionality enables fine-tuned binding and elution conditions that allow for distinct resolution of OC and SC plasmid forms, even under high flow rates. This supports faster processing with no compromise in isoform purity.

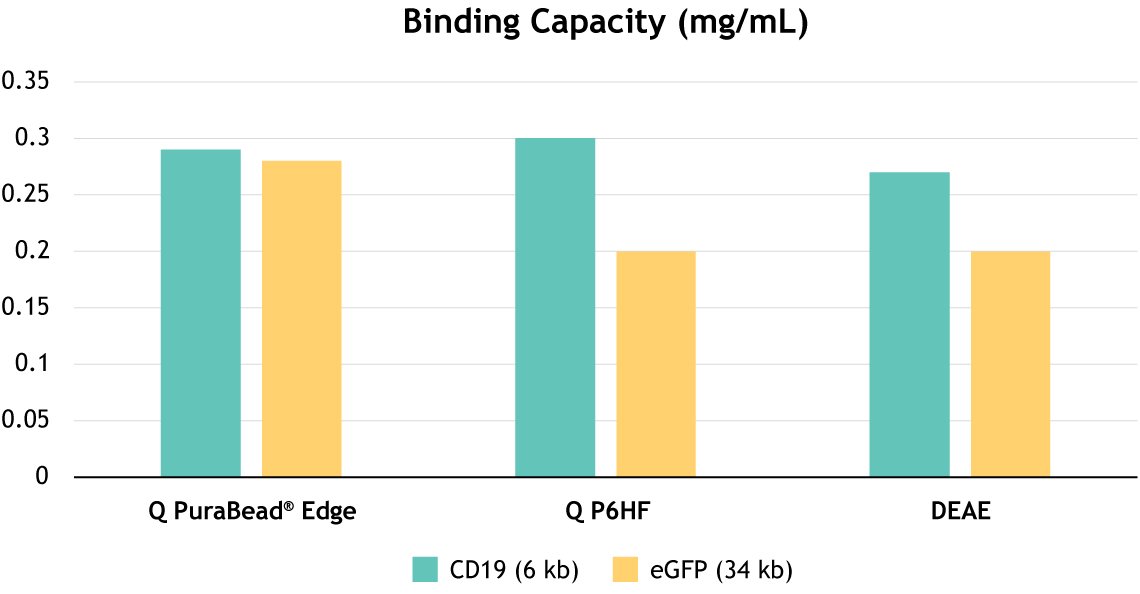

In addition to high-resolution separation, Q PuraBead® Edge demonstrates superior binding capacity across different plasmid sizes (Figure 4). While Q PuraBead® 6HF and DEAE resins showed reduced capacity for a large 34.7 kb plasmid, Q PuraBead® Edge maintained robust performance, suggesting it is well-suited for both small and large plasmid DNA applications. This ensures scalability and flexibility in manufacturing processes, particularly for gene therapy products requiring high plasmid loads.

Whether optimizing a new pDNA therapeutic or improving an existing process, Q PuraBead® Edge offers the resolution, capacity, and flow properties needed to meet stringent regulatory and functional requirements—delivering reliable results from discovery through GMP manufacturing.

_2025145-161206.jpg)

Figure 4: Comparison of binding capacities (mg/mL) for 6 kb and 34.7 kb plasmid DNA using Q PuraBead® Edge, Q PuraBead® HF, and DEAE PuraBead® resins. Q PuraBead® Edge showed consistently high capacity across both plasmid sizes, an advantage seen due the unique pore characteristics of the PuraBead® Edge bead.

In application: AAV8 purification

Q PuraBead® Edge offers an alternative solution for the separation of empty and full AAV8 capsids, making it an ideal choice for advancing gene therapy applications. By optimizing conductivity conditions, the resin effectively binds full AAV8 capsids while minimizing the capture of empty capsids, enhancing the purity of your final product.

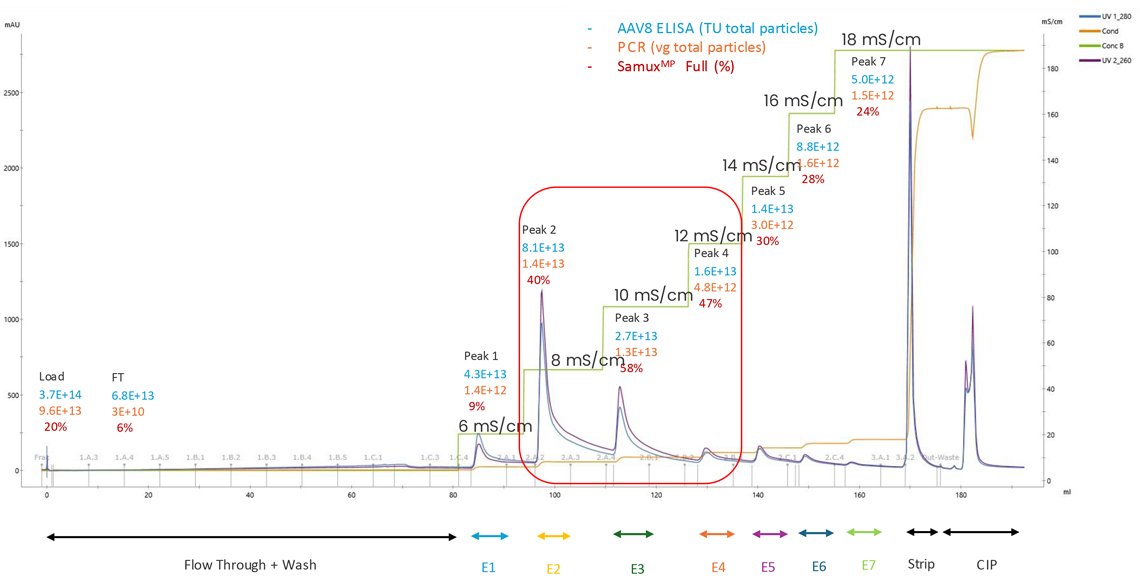

Initial studies showed that loading Q PuraBead® Edge resin at 4.5 mS/cm effectively binds full AAV8 capsids while minimizing column binding of empty capsids.

A Q PuraBead® Edge column loaded with purified AAV8 at 4.5 mS/cm, containing 3.7 × 10¹⁴ total particles (TP) and 9.6 × 10¹³ vector genomes (VG), with 20% full capsids and was run using a step elution (6–18 mS/cm). Binding capacity was noted as 4.8 × 10¹³ VG/mL. Lack of full capsid breakthrough indicates that the full capsid capacity was not yet reached. Peaks 2, 3, and 4 (8–12 mS/cm) showed 2–3 fold enrichment, resulting in a 2.5-fold increase to ~50% full capsids when pooled (Figure 5).

With a binding capacity of 4.8 × 10¹³ VG/mL resin, potential for large-scale applications, while still offering room for further optimization to maximize full capsid binding has been demonstrated. The step elution process developed with Q PuraBead® Edge ensures efficient separation, achieving up to 3-fold enrichment of full capsids, and delivering a final pool with approximately 50% full capsids. The process was performed at short residence times (3 minutes residence time in all steps) with potential to increase further allowing excellent productivity.

Importantly, Q PuraBead® Edge offers several advantages over other existing technologies, including continuous scalability, robust cleaning and reuse capability, cost-effective operation, and can be used with standard chromatography equipment. Unlike other recognised technologies for AAV purification, which can be limited in scalability and may be limited to single-use operation or require expensive additional equipment, Q PuraBead® Edge can be cleaned and re-used over multiple cycles without additional equipment requirements. This significantly reduces production costs and waste. The pre-packed column format allows seamless scale-up from process development to manufacturing, supporting flexible batch sizes and enabling manufacturers to meet growing demand without major process redesigns. These combined features make Q PuraBead® Edge an attractive option for companies aiming to balance high performance, regulatory compliance, and operational efficiency across clinical and commercial manufacturing.

This targeted approach allows for scalable production, ensuring that the resin is effective in both small and large-scale processes. Whether you're looking to optimize production or improve the purity of AAV8 vectors, Q PuraBead® Edge resin provides an efficient, scalable solution for high-quality capsid enrichment.

Figure 5: Gradient elution profile of AAV8 capsids on Q PuraBead® Edge resin. Fractions were analysed for Total Particles (TP) by ELISA, Vector Genomes (VG) qPCR and % full capsids by Refeyn SamuxMP. Peaks 2-4 (8-12mS/cm) showed 2-3 fold enrichment of full capsids, increasing purity to ~50% in pooled fractions.

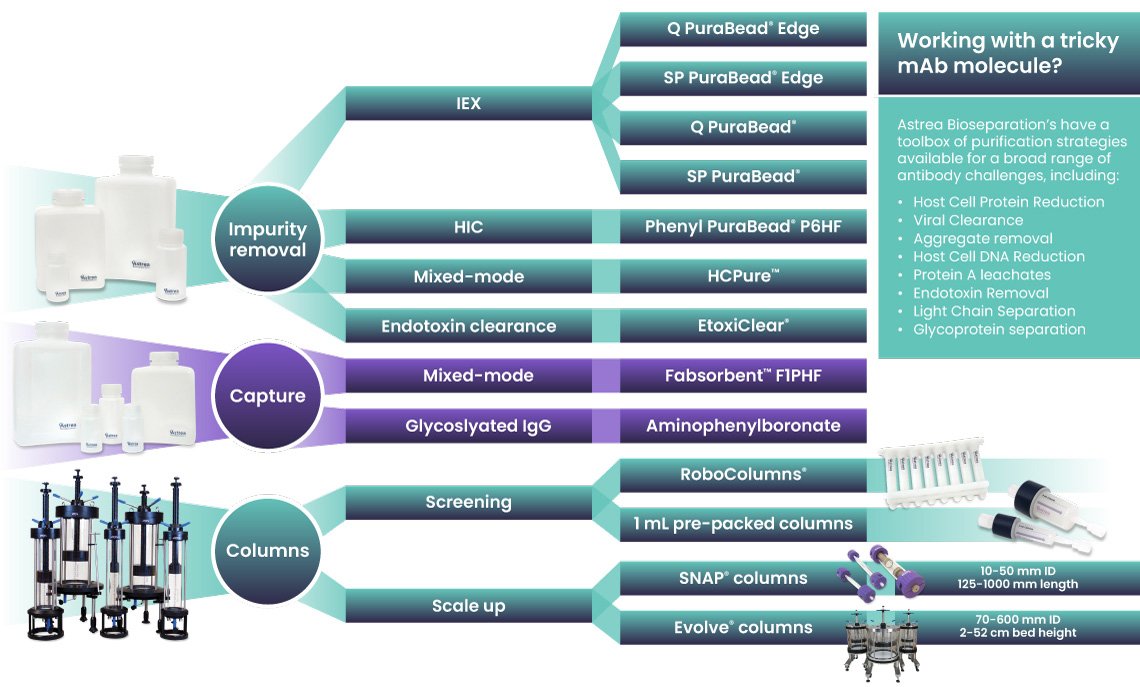

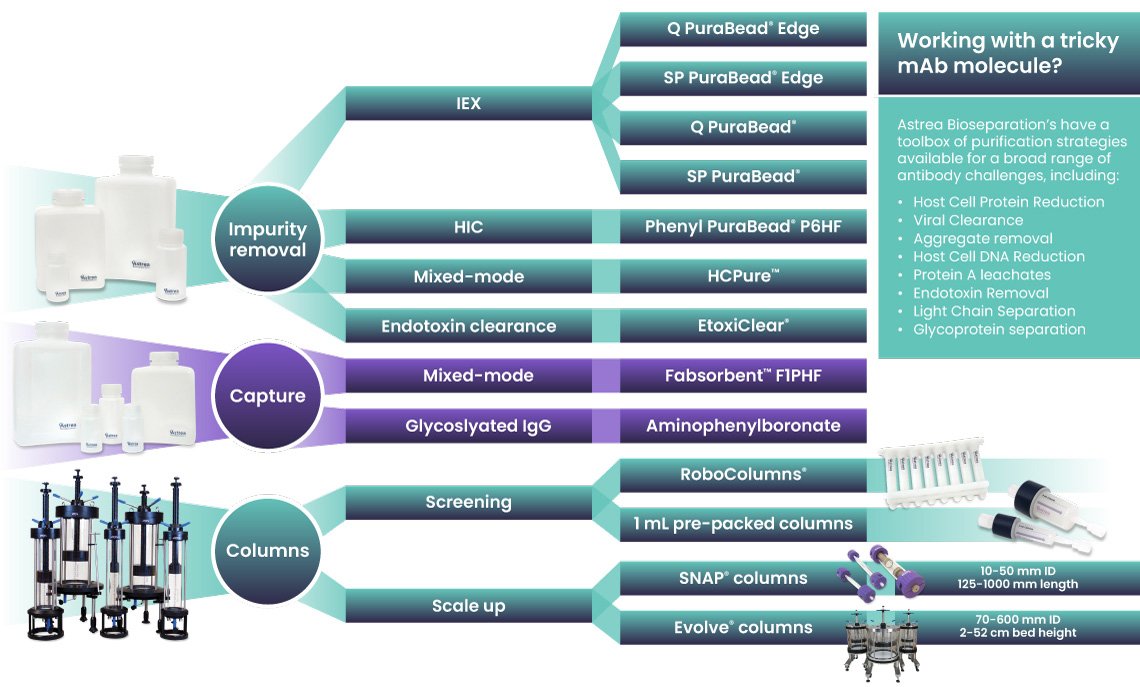

In application: A complete toolbox for antibody purification

As the demand for novel antibody formats grows, efficient screening of purification conditions becomes essential. Astrea Bioseparations has a broad range of purification resins, ranging from capture to polish, for mAb and other antibody formats. Using Astrea Bioseparations’ toolbox approach, products, such as Fabsorbent™ F1P HF, HCPure™, SP PuraBead® Edge, and Q PuraBead® Edge, provide the market with additional choices for downstream processing workflows. Resins are provided in high-throughput screening formats to streamline discovery and purification. Combining smarter purification strategies and high-throughput screening options will help shape the future of biopharmaceutical development and commercialization of new drugs.

Simplified workflow integration and scalability

Q PuraBead® Edge is designed for seamless integration into existing purification processes. Available in multiple column sizes for research or process-ready applications and bulk adsorbent slurry, ensuring scalability from lab-scale R&D to large-scale manufacturing.

Product specifications

| Feature | Description |

|---|---|

| Ligand | Quaternary ammonium group (Q) |

| Type of ion exchanger | Strong anion |

| Total ionic capacity | 80 to 117 µmol/g settled gel |

| Mean particle size (µm) | 65 ± 10 µm |

| Matrix | PuraBead® Edge (Highly cross-linked 6% near-monodisperse agarose) |

| Binding capacity | Up to 72 mg/mL of resin (BSA, 10% breakthrough) |

| Recommended packing conditions | Pack at a constant pressure of 1.5 bar |

| Recommended packing solution | 0.1 M NaCl solution or equilibration buffer |

| Recommended operational flow rates | Up to 300 cm/h |

| Operating pH | pH 2.0 to pH 14.0 |

| Chemical stability | All commonly used aqueous buffers and co-solvents |

| Cleaning/sanitization | 0.5 to 1.0 M NaOH |

| Sterilization | Autoclavable in 0.1 M NaCl solution at 121°C for 30 minutes |

| Storage | 2–30°C, 20% ethanol |

Frequently asked questions

- Improved resolution using our 65 µm PuraBead® Edge base bead.

- Optimal balance of flow rate, binding capacity, and resolution to maximize productivity

- Demonstrated performance in multiple IEX high resolution requiring applications

- Efficient processing of large volumes

What formats is Q PuraBead® Edge available in?

Q PuraBead® Edge is available in pre-packed columns ready to plug into your research or GMP process. It is also available in slurry format.

- Across broad range of applications and feedstocks

- Where high resolution polishing with short residence times and low back pressure is required

What tools do Astrea Bioseparations have for antibody purification?

Astrea Bioseparations has a broad range of purification resins, ranging from capture to polish, for mAb and other antibody formats. Using Astrea Bioseparations’ toolbox approach, products, such as Fabsorbent™ F1P HF, HCPure™, SP PuraBead® Edge, and Q PuraBead® Edge, provide the market with additional choices for downstream processing workflows. Resins are provided in high-throughput screening formats to streamline discovery and purification. Combining smarter purification strategies and high-throughput screening options will help shape the future of biopharmaceutical development and commercialization of new drugs.

Related Products

Recently Viewed

There are no recently viewed products.

No video available.