Unleashing the Potential of Nanofiber Composites: Advancements in Purification and Beyond

Published date: 12 December 2023

Nanofiber composites are effective in purifying biological substances, including proteins, nucleic acids, carbohydrates, bacteria, viruses, cells, and exosomes and are suitable for all fluid applications, whether liquid or gaseous. However, they aren’t only limited to biological functions; Nanofiber composite materials are valuable in industrial applications, such as, providing textile reinforcement, protective clothing, catalytic media, agricultural applications, and sensors for environmental and medical monitoring, as well as in biomedical fields such as bioseparation and tissue engineering.

Additionally, biologically based diagnostic and therapeutic tools are widely utilized for high-throughput testing of biological substances, such as recombinant proteins, monoclonal antibodies, and viral vaccines, which require efficient production and purification.

The biopharmaceutical therapeutics industry is currently witnessing substantial growth, driven by the increasing number of approved biopharmaceuticals. However, traditional purification methods like ion-exchange (IEX), hydrophobic interaction (HIC), and affinity-based adsorption/chromatography present challenges and high manufacturing costs. This is mainly attributed to the intricate process of producing and purifying biological ligands, such as monoclonal antibodies and nucleic acids. These ligands are also highly sensitive to environmental conditions, such as temperature and pH, and are prone to degradation, which can disrupt the necessary affinity interaction for effective adsorption.

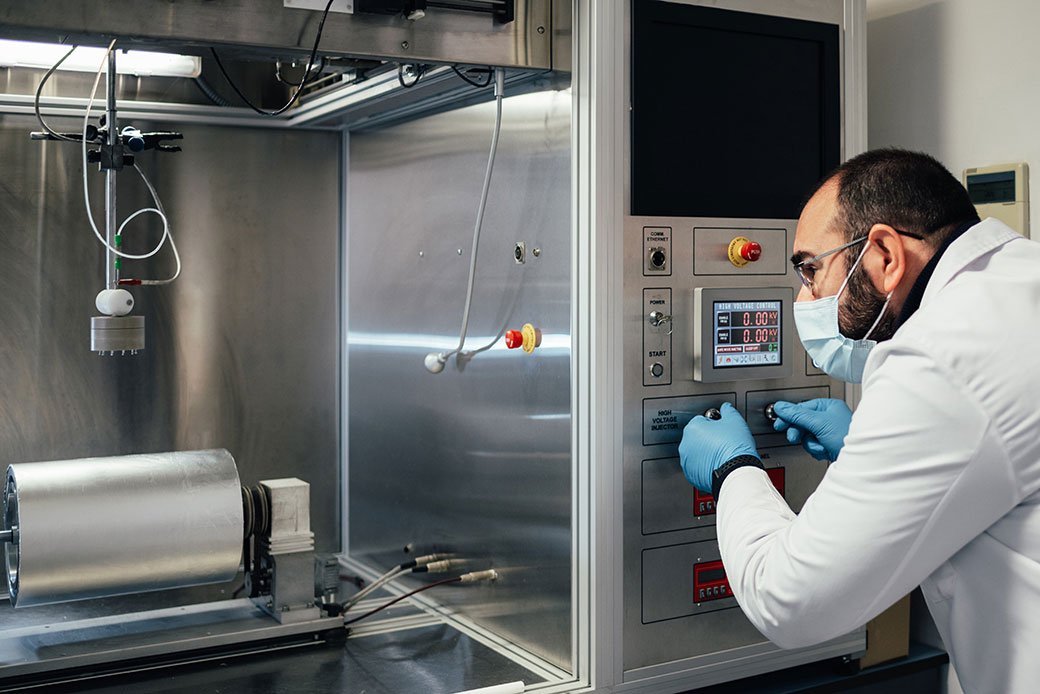

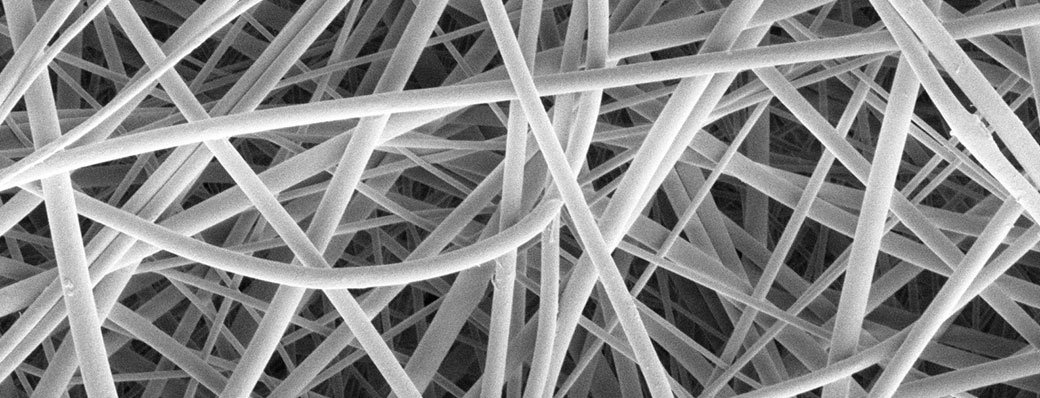

Nanofiber membranes (fig. 1) designed for the purification of biological substances have been described recently as showing great promise for bioseparations. Single-component nanofibers are superior to single-component microfibers because they allow for more precise control over pore sizes, affinity characteristics, and other performance criteria. However, while these single-component nanofiber structures have yielded promising results, they often exhibit lower efficiency in terms of stability and time requirements. Therefore, there is a need to enhance the stability of these single-component nanofiber structures and improve the purification efficiency of biological products.

Figure 1. SEM of composite Nanofiber membrane

Electrospun nanofibers have found applications in various fields, ranging from separation science to clinical translation. In the field of separation science, electrospun nanofiber membranes have extensively served as sorbent materials for solid-phase extraction techniques, primarily due to the need to enhance sorptive capacity and analyte selectivity.

The research community has been inspired by the resemblance of electrospun nanofibers to the morphology and mechanical properties of fibrous extracellular matrices (ECM) found in natural human tissues. As a result, electrospun nanofibrous composites and membranes have been explored as analogs of ECM for specific tissue cells, stem cells, and tumor cells, aiming to achieve tissue regeneration, stem cell differentiation, and the construction of in vitro tumor models. It is important to note that the nanofiber fabrication technique and material integrity are crucial factors in obtaining clinically relevant nanofibers. Due to the impact of fiber arrangement on nanofiber performance, electrospinning has a significant advantage over other nanofiber fabrication techniques (e.g., drawing or phase separation) because of its ability to control fiber orientation easily. Some of the unique benefits of electrospun nanofibers are below:

A variety of nanofibrous structures can be constructed using advances in electrospinning setup and processes. These structures have shown the ability to replicate properties found in complex structures in the human body (e.g., heart valves and arteries) or used in wearable electronic devices like biosensors. Modifications to the electrospinning setup include:

Electrospinning scale-up

The growing interest and research in electrospinning have led to increased competition among suppliers of laboratory-scale equipment. Several companies have successfully adapted the electrospinning concept for spinning nanofibrous membranes at an industrial scale. Commercial electrospinning setups for mass production of nanofibers are now available in the market.